Aluminum Gutters: Benefits, Installation Tips, and Maintenance Guide

Outline:

1. Material basics and comparisons: aluminum versus vinyl, galvanized steel, copper, and zinc.

2. Sizing, profiles, and components: choosing 5-inch or 6-inch K-style or half-round, and matching downspouts.

3. Installation planning and safety: DIY methods, tools, and when to hire a professional.

4. Maintenance and troubleshooting: cleaning, guards, leak repair, and seasonal concerns.

5. Costs, lifespan, and sustainability: budgeting, warranties, and environmental benefits.

Aluminum gutters might look like a simple metal ribbon at the eaves, but they quietly shape how rain behaves around your property. Chosen well and cared for regularly, they keep fascia dry, foundations stable, and landscaping intact. The following sections translate material science and jobsite know-how into practical steps you can use right away.

Material Basics and Comparisons: Why Aluminum Stands Out

Aluminum gutters earn their place on countless homes because they balance durability, weight, and cost. Aluminum is naturally corrosion-resistant thanks to a thin oxide layer that forms on its surface. Unlike bare steel, which can rust, aluminum resists moisture, making it suitable for humid regions and storm-prone seasons. Compared with vinyl, aluminum handles temperature swings better, resists brittleness, and can be painted in long-lasting finishes. At the same time, it is lighter than steel, easing installation and reducing load on fascias.

How does aluminum compare with other common materials? Vinyl is typically the least expensive up front and easy to cut, but it can warp in intense heat, crack in deep cold, and fade faster under UV exposure. Galvanized steel is stronger and more impact-resistant than many aluminum profiles but can be susceptible to corrosion once its zinc coating is compromised; it also weighs more and may require heavier fastening. Copper and zinc are prized for long service life and a graceful patina; they tend to be premium options with significantly higher material cost and more specialized installation techniques. Aluminum sits between these extremes: accessible pricing, compatible with seamless systems, and widely supported by installers.

Numbers help frame the trade-offs. Aluminum’s density is about 2.7 g/cm³, roughly one-third that of carbon steel, which explains its manageable weight on a ladder. Its coefficient of thermal expansion—about 23 µm/m·°C—is higher than steel’s, so joints and fasteners must accommodate seasonal movement. Thickness matters too: common aluminum gutter stock ranges from 0.027 inch for budget work to 0.032 inch for standard residential use and 0.040 inch for heavy-duty applications in snow country. Thicker stock better resists dents and ice loads but increases cost.

Cost ranges vary by region and complexity, but typical installed pricing for standard 5-inch seamless aluminum can fall into the moderate bracket for many households, while 6-inch profiles and specialty colors add a premium. Consider the full system, not just the trough: downspouts, elbows, miters, outlets, and hanger style influence longevity and performance. A practical mental checklist includes:

– Climate exposure: salt air, hail, freeze-thaw cycles, and tree density around the roofline.

– Desired appearance: painted finishes, half-round versus K-style profile, and trim compatibility.

– Serviceability: availability of local installers, standard component sizes, and ease of repair. The net effect is a material that delivers reliable water control without excessive weight or upkeep, which is why aluminum remains a well-regarded choice for many homes.

Sizing, Profiles, and Components: Matching Capacity to Your Roof

Aluminum gutters come in two widely used profiles: K-style and half-round. K-style features a flat back and decorative front that boosts capacity relative to its width; it blends with many architectural styles and is common in 5-inch and 6-inch sizes. Half-round gutters curve like a semicircle, offering a classic look and smoother flow paths that can reduce debris accumulation, though they usually need larger diameters to match K-style capacity. For most single-family homes, 5-inch K-style is standard, while 6-inch is often selected for larger roof areas, steep pitches, or regions with intense downpours.

Downspout sizing is integral to an effective system. A rule of thumb many installers use is one 2×3-inch downspout for roughly 600–800 square feet of roof area under moderate rainfall, and one 3×4-inch downspout for up to about 1,200 square feet. Rainfall intensity matters: in areas where short bursts can exceed 2 inches per hour, upsizing to 6-inch gutters and 3×4-inch downspouts helps reduce overflows. Slope also matters. Aim for about 1/16 inch of fall per linear foot toward the outlet; in stubborn problem areas or long runs, 1/8 inch per foot may be appropriate. Long eave lines can benefit from a center outlet that drains in two directions or from splitting the run into shorter segments.

Thickness and hangers work together to resist loads. In mild climates, 0.032-inch aluminum offers a balance of rigidity and weight. In snow regions, 0.040-inch stock with robust hidden hangers—spaced 24 inches on center, or as tight as 18 inches where snow and ice accumulate—helps prevent sagging. Fasteners should be corrosion-resistant; exterior-grade screws with rubber or EPDM washers are common on exposed brackets, while hidden hanger systems use coated or stainless fasteners to anchor into the rafter tails or solid blocking.

An aluminum system is more than a trough and a pipe. Key components to plan include:

– Outlets and miters: properly sized and sealed to control corners and transitions without bottlenecks.

– Elbows and offsets: gentle turns maintain flow and reduce clog points, especially above ground-level bends.

– Splash blocks or extensions: discharge water 4–6 feet away from foundations to limit settlement and seepage. By organizing these parts with your roof area, pitch, and local rain patterns in mind, you build a system that can move water predictably—even when storms arrive with little warning.

Installation Planning and Safety: DIY Steps and When to Hire

Installing aluminum gutters rewards careful planning. Start by walking the perimeter and noting where water naturally wants to go. Choose downspout locations that avoid doorways and high-traffic paths, and plan extensions that push water several feet from the foundation. Use a level and chalk line to mark slopes: 1/16 inch per foot is a reliable starting point. If you’re tackling a long run—say, over 40 feet—consider a center drop and pitch in both directions to reduce standing water and visual slope.

Gather tools before you climb. A measuring tape, snips, a drill/driver, a crimper, rivet gun, sealant rated for exterior metal, and safety gear are essentials. Hidden hangers are popular because they offer a clean look and strong support; pre-lay them out along the chalk line at 24-inch spacing, tightening to 18 inches in cold or snowy regions. When attaching to fascia, aim for structural members (rafter tails or added blocking) rather than relying on thin trim alone. If fascia is deteriorated, repair it before hanging any new metal.

For sectional aluminum, common lengths are 10–12 feet. Dry-fit pieces on the ground, then assemble on ladders using slip joints, rivets, and sealant to create drip-proof seams. Sealant selection matters: high-quality elastomeric or polyurethane products maintain flexibility as the metal expands and contracts. Keep joints slightly proud, then tool the bead to shed water. At corners, use box miters or strip miters; pre-assemble and test for fit before permanent fastening.

Ladder safety is non-negotiable. Maintain three points of contact, use a stabilizer to straddle gutters without crushing them, and never overreach—climb down and reposition. If you plan to bury downspout extensions, call utility locators before digging. Know when to hire a professional: seamless systems require a roll-forming machine to produce continuous lengths from coil stock, minimizing joints and leak risks. Homes with complex rooflines, multiple inside and outside corners, or high eaves also benefit from experienced installers. A straightforward DIY project becomes far smoother when you respect the details:

– Pre-measure outlets and cut clean, burr-free holes to avoid catch points.

– Deburr snipped edges and cap ends securely to stop drips.

– Test flow with a hose before finalizing, checking for ponding or backflow. Measured steps save time now and prevent callbacks later—especially when the first thunderstorm tests your work.

Maintenance and Troubleshooting: Keep Water Moving

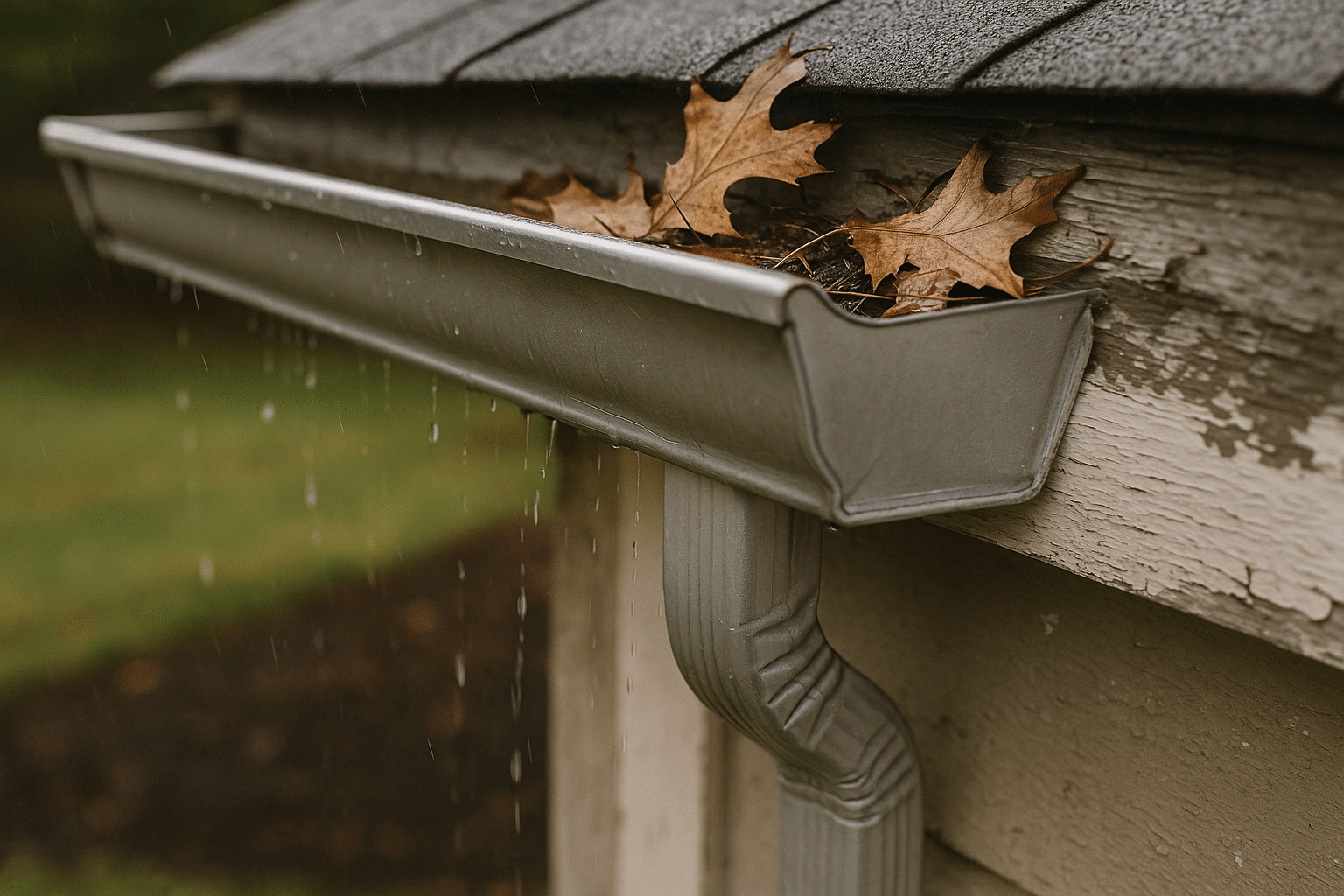

Even well-installed aluminum gutters need routine care. Leaves, twigs, asphalt shingle granules, and nesting materials can collect at outlets and elbows, slowing flow and triggering overflows at the worst time. Plan to clean twice a year—typically late spring and late fall—and increase frequency if you live under shedding trees. Work on a dry day, scoop debris by hand with gloves, and flush toward outlets with a garden hose. A nozzle with a gentle fan pattern helps avoid blasting water under shingles.

Gutter guards can reduce, but not eliminate, cleaning. Perforated covers and micro-mesh screens block larger debris while allowing rain to pass; they still require brushing or rinsing off pollen mats and fine needles. Foam inserts are simple to place but can trap seeds or break down under UV. Solid-surface covers shed leaves but may struggle in extreme downpours if the nose profile isn’t pitched or sized properly. If you install guards, confirm that outlets remain accessible for periodic flushing and that fasteners do not pierce the gutter’s critical water channel.

Leaks typically appear at miters, end caps, and outlet seams. Inspect sealant beads annually; if you see cracks or peeling, remove old material, clean with mild detergent, rinse, and dry completely before re-sealing. For small pinholes or pitting near the waterline—more common in coastal air—lightly abrade, clean, and apply compatible patch sealant. Sagging sections indicate loose hangers or undersized spacing; tighten or add hangers, ensuring the run maintains even fall. During winter, watch for ice dams formed by heat loss at the roof edge; they can overload gutters. Improving attic insulation and ventilation helps, and snow guards on metal roofs can slow sudden slides that stress the system.

Down at grade, confirm that extensions discharge well away from the foundation. Splash blocks are better than nothing, but hinged or rigid extensions that reach 4–6 feet are more effective on flat lots. A few quick cues make inspections more productive:

– After a storm, walk the perimeter and look for streaking on siding, washouts in mulch, and damp basement smells.

– Check the ground around outlets for erosion; this hints at insufficient spread or missing diffusers.

– Watch for paint chalking on gutters; chalking is cosmetic but signals weathering, and a gentle clean-and-recoat can refresh appearance. Maintenance is not glamorous, yet a steady routine keeps the water where it belongs: moving quietly away from your home.

Costs, Lifespan, and Sustainability: Budgeting and Long-Term Value

Budgeting for aluminum gutters requires looking beyond the headline price per linear foot. Material thickness, profile, color, and the number of corners, outlets, and downspouts all influence the final number. Standard 5-inch seamless aluminum often lands in a middle price tier, with 6-inch profiles, complex rooflines, and specialty finishes pushing costs higher. Add disposal of old gutters, new fascia repair if needed, and accessories like leaf guards or downspout extensions. Labor varies with ladder height, site access, and the installer’s schedule, so getting a few local quotes with detailed line items is wise.

Service life depends on climate, exposure, and upkeep. Many aluminum systems deliver two to three decades of use under normal conditions, with coastal salt spray and heavy snow loads shortening that window. Factory-applied architectural coatings can slow chalking and color fade, while thicker 0.040-inch stock and robust hanger layouts help resist deformation. Warranties often cover the finish for a set period and workmanship for a shorter term; read the terms closely to understand what is included and what routine maintenance the warranty expects.

From a sustainability standpoint, aluminum brings several advantages. It is highly recyclable, and recycled aluminum typically requires about 95 percent less energy to produce than primary aluminum. Many gutter coils contain recycled content, and the metal can be recycled at end-of-life, reducing landfill waste. Good water management also protects landscaping and soil, reducing sediment transport to storm drains. If you collect rainwater for barrels or cisterns, aluminum plays nicely, provided you keep the system clean and use appropriate first-flush diversion and screening.

For homeowners deciding between a fresh install and patchwork repairs, a simple framework helps:

– If multiple seams leak or runs are visibly distorted, replacement with seamless sections can reduce chronic maintenance.

– If capacity is marginal during intense storms, upsizing to 6-inch gutters with 3×4-inch downspouts often improves performance.

– If the fascia is compromised, address the substrate first; new gutters on weak wood rarely stay straight. Ultimately, the most effective system is the one you can maintain consistently.

Conclusion: A Practical Path to Dry Foundations

Aluminum gutters offer an approachable path to reliable rain control: light enough for straightforward handling, sturdy enough for four-season duty, and adaptable to the quirks of most rooflines. If you match size to rainfall, install with careful slope and fastening, and keep outlets clear, they will quietly protect your home for years. Use the guidance above to specify the right profile, plan clean downspout routes, and set a maintenance rhythm that fits your property. When the clouds gather, you’ll have more peace of mind—and fewer puddles where they don’t belong.